Real Importer of Record Operations: What Actually Works and What Breaks

This article is written to explain how real IOR operations work in practice, based on field experience across multiple jurisdictions.

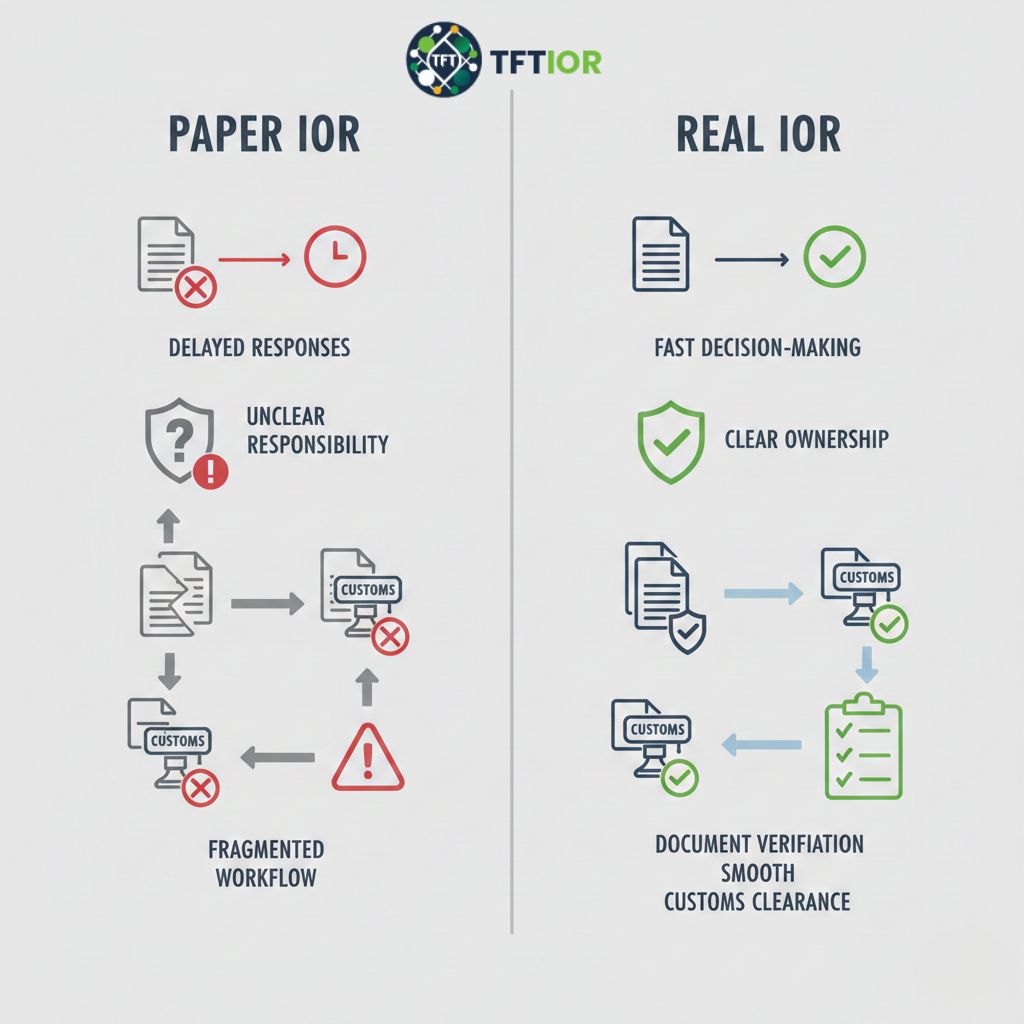

Importer of Record (IOR) services are often presented as simple on paper. A contract is signed, paperwork is exchanged, and goods are expected to clear customs smoothly. In real operations, this is rarely the case.

What determines success is not the existence of an IOR agreement, but who actually carries responsibility when regulations, inspections, or unexpected risks arise.

The Core Problem with Paper IOR Models

Many global IOR models rely on networks, intermediaries, or loosely connected local partners. On paper, this looks scalable. In real customs operations, it introduces three structural failures:

- No Liability Means No Decision Power: When customs authorities raise questions, a clear decision must be made. In paper IOR structures, no single party fully owns the risk, decisions are delayed, and clients absorb time loss and unexpected costs.

- Networks Exist, Ownership Does Not: A common misconception is that a local partner equals local execution. In reality, HS code confirmation may take days and quotations may never materialize.

- Poor Communication Creates Artificial Costs: Delays are rarely caused by regulations alone. On principle, we follow: Bad news first followed immediately by solutions.

Case Example: Vietnam Speed and Clarity

Before handling a Vietnam deployment, we evaluated multiple local providers. The findings were consistent: inability to confirm HS codes independently and long response cycles. By contrast, our product analysis was completed immediately, pricing was realistic, and customs clearance was completed in two days.As a result, the client continued working with us for additional country deployments.

Case Example: Mexico Recovering a Failed Shipment

A client attempted to ship refurbished equipment to Mexico using an express courier. The shipment was stopped. Rather than forcing an unworkable path, the client accepted a return and re export. A compliant import structure was rebuilt, and final delivery met the original deadline.

Turkey: Where Real IOR Capability Is Actually Tested

Turkey is often underestimated in global IOR planning. It is one of the most demanding environments due to layered oversight. While many providers avoid risk, we routinely handle:

- Refurbished infrastructure for major hosting environments.

- Financial sector installations requiring CE, EPREL, and TSE alignment.

- Complex meeting room systems with mixed compliance requirements.

Despite additional inspections, no shipment has ever been abandoned or returned. Every case was resolved through correct explanation and technical alignment.

When Saying No Is the Correct IOR Decision

In one case, a global intermediary attempted to remove regulated components from documentation to simplify clearance. We requested a pre customs inspection, verified actual contents, and identified non declared regulated equipment. We corrected the shipment but declined subsequent requests from the same intermediary. IOR credibility is built as much by refusing unsafe structures as by completing difficult ones.

IMEI Registration for Embedded Tracking Devices

IMEI registration is widely avoided due to perceived risk. For a UK based company importing pallet level tracking devices, we completed IMEI registration within three days. Import clearance followed immediately, and the project transitioned from test shipments to regular operations.

When IOR Should Not Be Used At All

IOR is not a universal solution. For an organic food company planning direct to consumer sales in Turkey, IOR was deemed unsuitable due to KVKK and consumer data risks. Local incorporation was recommended instead. Without financial obligation, we introduced them to trusted tax advisors and customs firms. Sometimes, the correct IOR decision is not to act as IOR.

How We Monitor Procedures

IOR operations require continuous regulatory awareness.This monitoring is not periodic research, but part of daily operational execution.We track customs updates, compliance enforcement trends, and procedural changes impacting electronics, telecom, and medical goods. This is ongoing operational discipline.

Why This Page Exists

This page exists to clarify reality. IOR works when responsibility is owned, communication is immediate, and ethics override short term gain. Real IOR value is created when clients are not forced to become customs or compliance experts themselves.

Frequently Asked Questions

What is the difference between a real IOR and a "paper IOR"?

A real Importer of Record assumes full legal and operational responsibility. A "paper IOR" model often exists only contractually, without clear ownership of risk or local execution capability.

Why do global IOR networks struggle in countries like Turkey or Vietnam?

Because local enforcement practices and documentation expectations vary significantly. Global networks relying on indirect partners often face delays and diluted responsibility.

Do experienced IOR providers ever refuse to act as Importer of Record?

Yes. Refusing to act as IOR can be the correct decision when regulatory, legal, or ethical risks outweigh the benefits. Choosing the correct structure protects long term operational integrity.

How does ongoing regulatory monitoring affect IOR success?

IOR success depends on continuous monitoring of customs procedures and enforcement trends, including changes applied in practice before they are formally published.

Need Real Operational Ownership?

Stop dealing with paper networks. Work with a partner that owns the risk and provides immediate solutions.

Discuss Your Import Structure